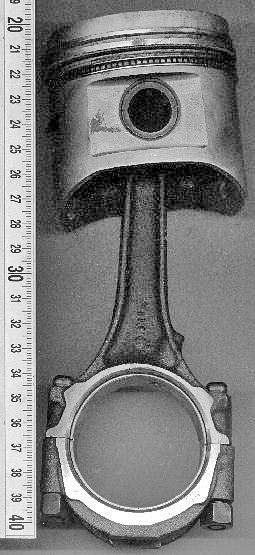

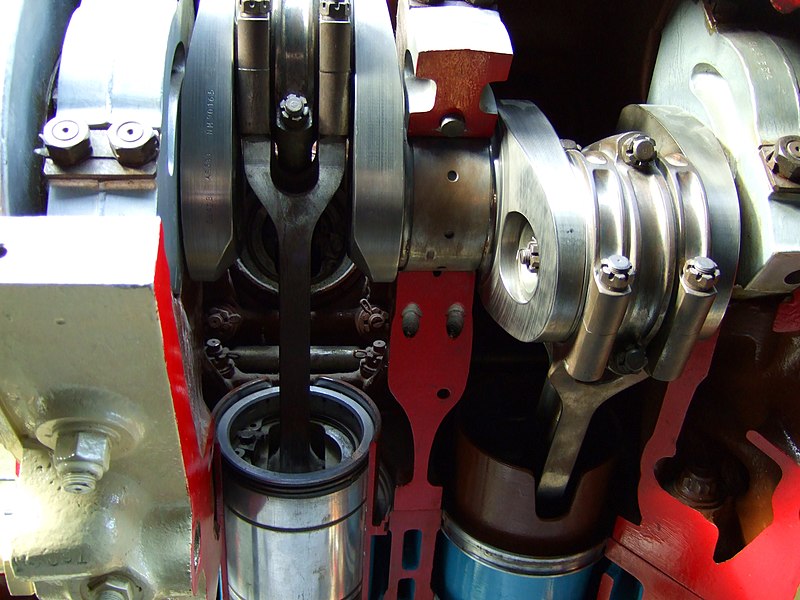

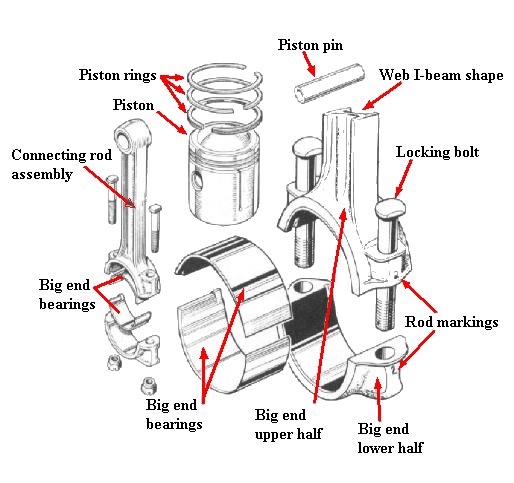

In a reciprocating piston engine, the connecting rod or conrod connects the piston to the crank or crankshaft. Together with the crank, they form a simple mechanism that converts linear motion into rotating motion.

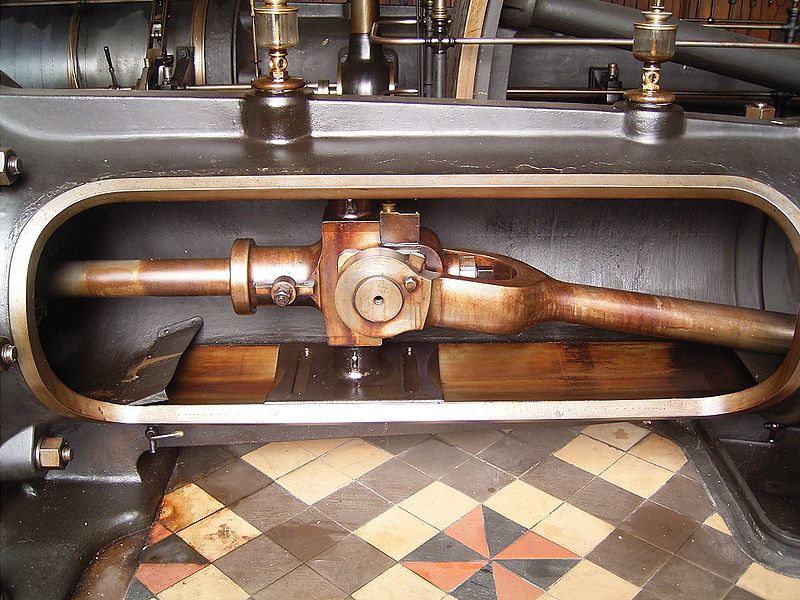

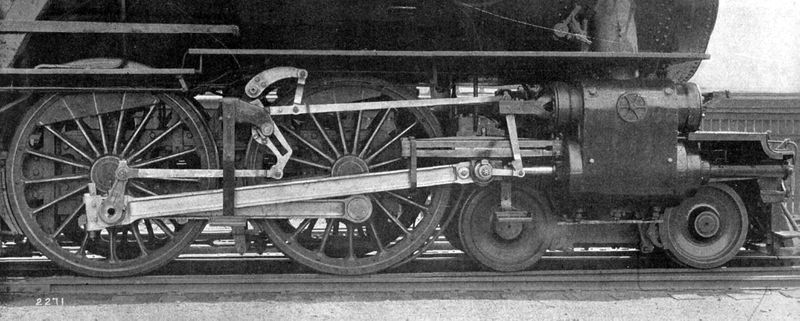

Connecting rods may also convert rotating motion into linear motion. Historically, before the development of engines, they were first used in this way.

As a connecting rod is rigid, it may transmit either a push or a pull and so the rod may rotate the crank through both halves of a revolution, i.e. piston pushing and piston pulling. Earlier mechanisms, such as chains, could only pull. In a few two-stroke engines, the connecting rod is only required to push.

Today, connecting rods are best known through their use in internal combustion piston engines, such as car engines. These are of a distinctly different design from earlier forms of connecting rods, used in steam engines and steam locomotives.

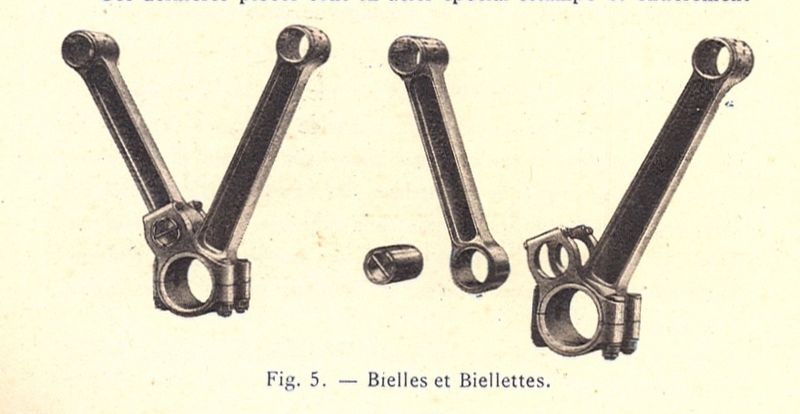

Compound rods

Many-cylinder multi-bank engines such as a V12 layout have little space available for many connecting rod journals on a limited length of crankshaft. This is a difficult compromise to solve and its consequence has often led to engines being regarded as failures (Sunbeam Arab, Rolls-Royce Vulture).The simplest solution, almost universal in road car engines, is to use simple rods where cylinders from both banks share a journal. This requires the rod bearings to be narrower, increasing bearing load and the risk of failure in a high-performance engine. This also means the opposing cylinders are not exactly in line with each other.

In certain engine types, master/slave rods are used rather than the simple type shown in the picture above. The master rod carries one or more ring pins to which are bolted the much smaller big ends of slave rods on other cylinders. Certain designs of V engines use a master/slave rod for each pair of opposite cylinders. A drawback of this is that the stroke of the subsidiary rod is slightly shorter than the master, which increases vibration in a vee engine, catastrophically so for the Sunbeam Arab.

Radial engines typically have a master rod for one cylinder and multiple slave rods for all the other cylinders in the same bank.

The usual solution for high-performance aero-engines is a "forked" connecting rod. One rod is split in two at the big end and the other is thinned to fit into this fork. The journal is still shared between cylinders. The Rolls-Royce Merlin used this "fork-and-blade" style

.